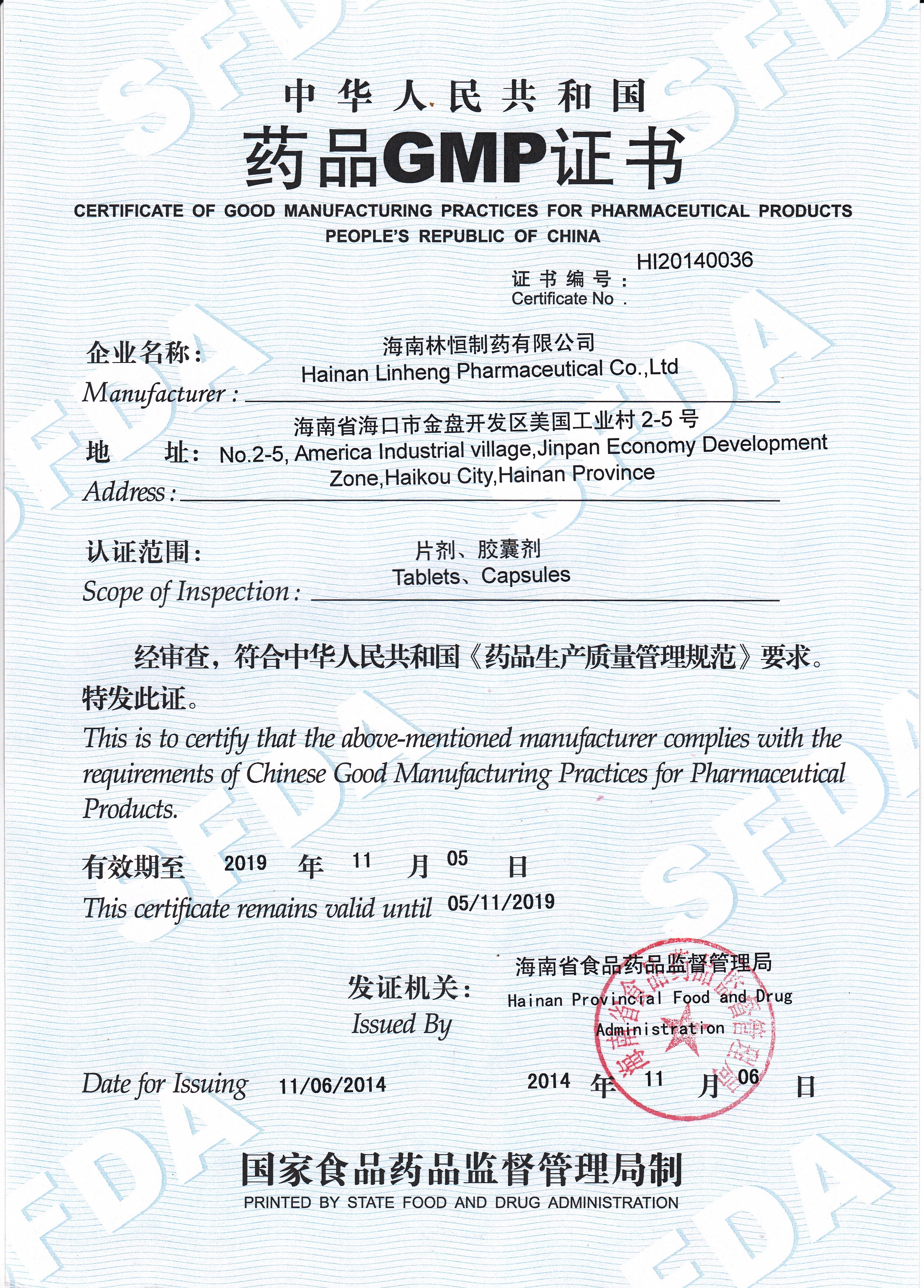

According to the law, GMP certification is the mandatory system for a country to supervise and inspect pharmaceutical production enterprise and drug variety implementation, is also a kind of advanced management method of science to ensure drug quality stability, safety and efficacy. On March 1, 2010, our country's new "GMP certification examination evaluation standard" come into effect. New standard require pharmaceutical enterprises must realize "zero serious defects" in their factories.

On November 6, 2014, accompanied by the leadership of the municipal Food and Drug Administration, the expert group carried out the GMP certification through the field inspection. After fully preparation, GMP certification experts visit our company to inspect the dynamic of the scene from the software to the hardware of our company. This is the most key step of the new version of the GMP certification which included production environment, facilities, personnel qualification, production management, quality management, and other parties. By 3 days inspection, the expert gave a brief report about 3 days checking result and fully affirmed the GMP general foundation work of three formulations includes tablet, capsule, and granule of our company.

Our success of passing the inspection is not only a new starting point for the development of our company, but also marks the company further enhance GMP standardized management level. And that is a good foundation for our company’s further development.